This product Gross weight about12.5kg per roll, washing test more than 50 times and the materials used in the film are environmentally friendly materials and have passed OEKO-TEX,SGS certification.The lettering film needs to be used according to computer cutter Plotter,press about 20-30pounds,the peeling method is hot peeling,temperature about 150-160°C.Product features are soft,easy cut and weed.

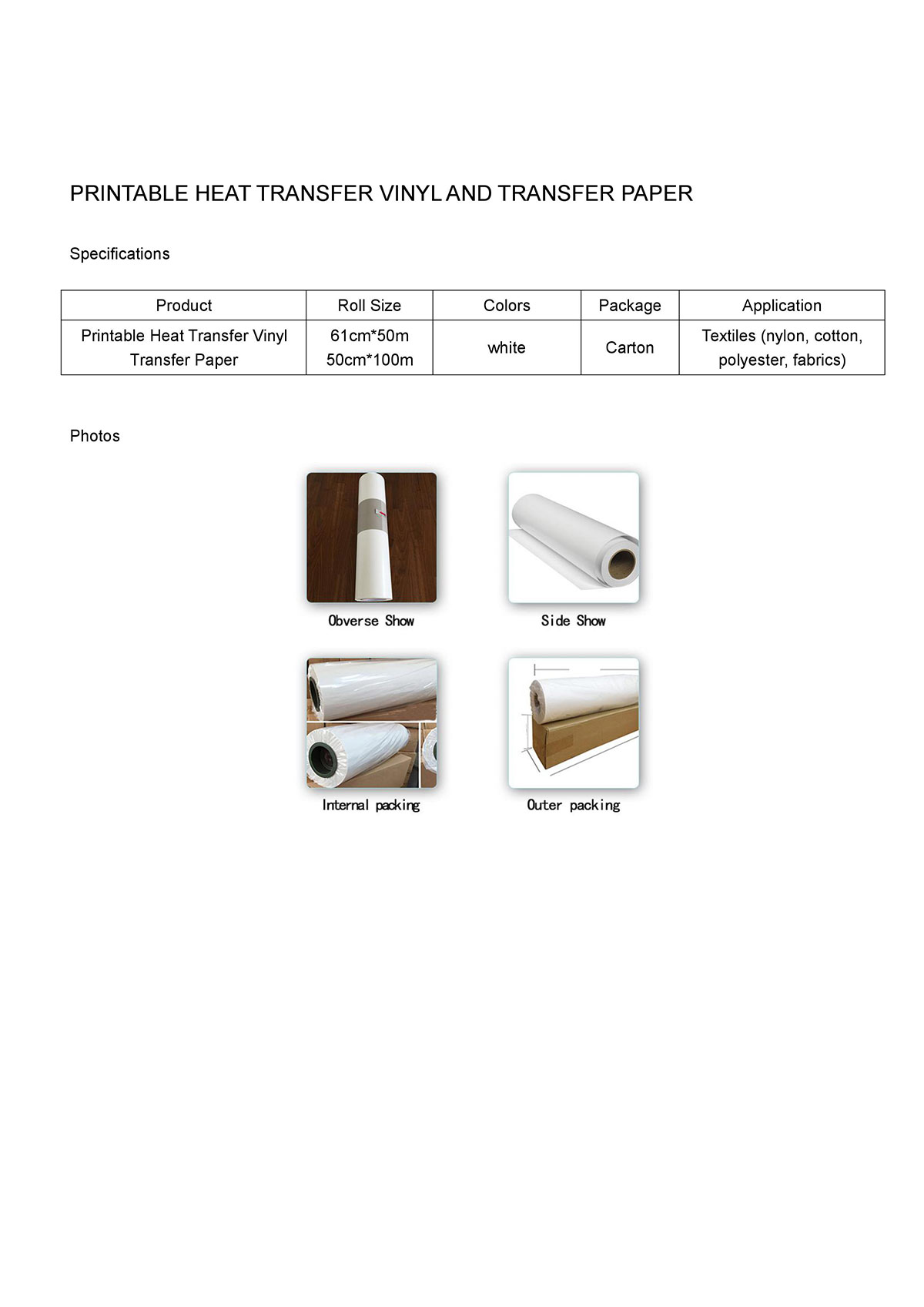

The color of this product is mainly white The conventional size is 60cm * 50m , the thickness is about100-130um. It can also be customized according to customer requirements. Film special letering texture og product and the computer must be supporting the use of cutting plotter and heat press machine(product without printing)very convenient,but also chromatic transfer,in order to increase the richness and bariability commitment should matter,and is not limited to the color of the fabic.As long as the fabic material of textile products all can transfer,after the trtansfer has excellent washing fastness.The products are widely applied to a monochrome graphics,team uniforms team logo,sports numbers,signs,advertisemens,posters,company logo,etc

The products are mainly applied to cloth,cotton,nylon,polyester,fiber.This products are suitable for text and graphics,used on textile fabrics,shoes,leather and bags products,Also suitable for oxford cloth and non-woven.Attention clothes with a waterproof costing of all can not be printed,mettal products,ceramic,plastic wood can not be printed.

How to use the film:1.Before using the film ,peel the protective liner to expose the adhesive or cutting part of the film.(these instructions are printed on that said liner)

2.feed the vinyl into your plotter or cutting machine.Material will not require any special settings.

3.Using a vinyl weeding tool or hook,remove the excess vinyl from the printedd sheet,leaving only the part of the design you wish to transfer to the fabic.

4.Place the graphicnoto the target area.Make sure the surface is flat,clean abd free from any residue.has a built-in transfer surface.No transfer paper needed.

5.Using a press or iron,apply medium pressure with an iron set to 305°f/150°C for approximately 25-40 seconds.

6.After the garment has fully cooled slowly remove the transfer paper.If the design lifts,replace the cloth and iron again for another 10-15 seconds.